A California researcher is developing a remote soil moisture sensor that uses radio signals and would be many factors cheaper than those currently on the market.

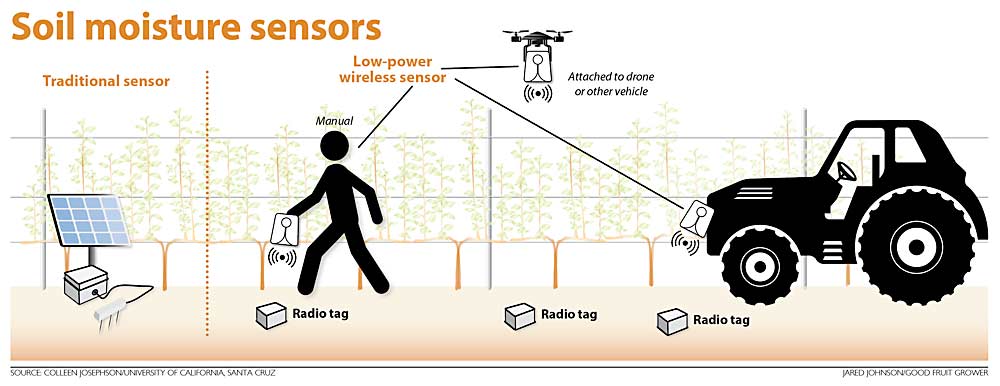

Colleen Josephson, an assistant professor of electrical and computer engineering at University of California, Santa Cruz, has built a prototype of a passive radio-frequency tag that could be buried underground and reflect radio waves from a reader aboveground, either held by a person, carried by a drone or mounted to a vehicle. The sensor would tell growers how much moisture is in the soil based on the time it takes for those radio waves to make the trip.

Josephson’s goal is to boost the use of remote sensing in irrigation decisions.

“The broad motivation is to improve irrigation precision,” Josephson said. “Decades of studies show that when you use sensor-informed irrigation, you save water and maintain high yields.”

However, current sensor networks are expensive, requiring solar panels, wiring and internet connections that can run thousands of dollars for each probe site.

Based on a hypothetical manufacturing run of 1,000 tags, she’s shooting for between $3 and $5 each. For more than one to compare depths, double that.

The catch is the reader would have to pass within proximity of the tag. She estimates her team can get it to work within 10 meters aboveground and as low as 1 meter deep in the ground.

Josephson and her team have built a successful prototype of the tag, a box currently about the size of a shoebox containing the radio frequency tag powered by a couple of AA batteries, and an aboveground reader.

Funded by a grant from the Foundation for Food and Agriculture Research, she plans to replicate the experiment with a smaller prototype and make dozens of them, enough for field trials on commercially managed farms. The trials will be in leafy greens and berries, because those are the main crops in the Salinas Valley near Santa Cruz, she said.

One aim is to determine how well the signal will travel through leafy canopies. So far, at the station, they have buried tags adjacent to drip lines down to 2.5 feet and are getting accurate soil readings.

Northwest irrigation experts lauded the idea — precision irrigation is indeed expensive — but had many questions.

Chet Dufault, a grower who uses automated irrigation tools, likes the concept but balked at the labor needed to bring the sensor into proximity of the tag.

“If you’re having to send someone or yourself … you can stick a soil probe in 10 seconds just as easy,” he said.

Troy Peters, biological systems engineering professor at Washington State University, questioned how soil type, density, texture and bumpiness affect readings and whether each location would need to be individually calibrated.

“It’s still interesting,” Peters said. “I sincerely hope they can make something work.”

Indeed, soil moisture monitoring can get expensive.

Probes that measure every 4 or 6 inches to a depth of 3 feet can cost $2,000 in today’s market, said representatives of Phytech and Semios, two companies offering data services in the Northwest tree fruit industry.

A few growers buy their own equipment, according to Iftach Shalev Rosenbach, Pacific Northwest regional sales manager for Phytech, an Israel-based ag data service company. But most of his clients opt for a service plan that involves renting a combination of soil probes, tree and fruit dendrometers and weather sensors, as well as the data analytics that come with the plan. Hundreds of sensors, installed and maintained by company technicians, communicate by radio with a single receiver powered by a solar panel up to 1,500 feet away, which then transfers data to the cloud. Battery life is not a problem, because those technicians visit each sensor at least once a year.

Probes are expensive when standing alone, but the value comes in the data analytics and maintenance service, Shalev Rosenbach said.

“It’s very complicated,” he said. “It’s not only about the cost sometimes.”

Josephson’s prototypes hearken back 30 years, said Ben Smith, technical irrigation specialist for Semios. He remembers gypsum block probes costing about $25 each, buried with exposed wires that a worker would physically plug into a handheld data logger.

Yes, sensors today are much more expensive, but with Semios, based in Vancouver, British Columbia, they come as part of an overall service plan that breaks down data on water, nutrients, climate, pests and more. For example, the company’s soil probes take measurements every 10 minutes, allowing analysts to spot trends.

“It’s less about the measurement in time than it is about the trend,” Smith said.

Josephson’s continued research aims to solve many of the riddles the Northwest tree fruit irrigators pose.

Part of her FFAR grant funds her work to overcome soil variability and canopy interference. Currently, general calibration will put it within 1 to 5 percent accuracy, about the same as existing sensors. Location-specific calibration would improve that, she said. The data collected by the receivers will be uploaded to an open-source analytics program her lab is building, so that growers or a commercial startup could use it.

Her system is not meant to compete with full-service providers like Semios and Phytech, she said, but rather to lower the cost of entry for smaller growers, so that everyone can use water more efficiently.

Farmers in developing countries would likely use handheld sensors to take readings, while in the United States — where only 10 percent of farmers employ soil sensing — she hopes to piggyback on the trend toward automated tractors, which could carry the reader. She is currently part of a project sponsored by the National Institute of Food and Agriculture to find ways to scale up autonomous soil sensing — mostly involving drones. But UC Santa Cruz has a farm-ng robot in nearby Watsonville that could allow for even more trials.

“Soil sensing has been so slow to adopt … that I believe simply making sensors affordable and easy-to-use enough to deploy at scale is the prerequisite to effectively answering those questions,” she said.

—by Ross Courtney

Leave A Comment