Editor’s note: An earlier version of this post incorrectly identified the SafePod manufacturer, Storage Control Systems, in the photo caption. Good Fruit Grower regrets the error.

Washington apple warehouses first became interested in dynamic controlled atmosphere storage techniques for organic apples, but they soon found the approach could minimize emerging storage disorders in new varieties that their primary tool, 1-MCP, did not.

That appeals to packers across the country.

Now, with a new $3.6 million grant from the U.S. Department of Agriculture’s Specialty Crop Research Initiative, postharvest scientists in New York, Michigan and Washington will study the best practices for using dynamic controlled atmosphere storage.

“We are co-learning with the industry,” said Christopher Watkins, a postharvest physiologist at Cornell University and principal investigator on the project. Gone are the days when warehouses would wait for industry scientists to set storage regimes for them, he said. There are simply too many new varieties.

“A number of them have storage disorders that 1-MCP does not improve or in fact exacerbates,” he said. “So, we’ve assembled this really strong team to look at what the (DCA) technology does to protect fruit quality and, most importantly, the economics of this higher-risk technology.”

While many warehouses are already investing in dynamic controlled atmosphere, research to understand the best practices and recommendations will help, said Emily Verbridge of the K.M. Davies Co., a storage supplier based in Williamson, New York. She serves on the project’s advisory committee.

“We’re very excited about the grant,” she said. “It’s trying to figure out the best storage techniques for these new varieties … which has huge economic benefit for growers because it gives them a better piece of fruit that can (be held) further into the season.”

Dynamic controlled atmosphere storage, or DCA, refers to the practice of monitoring and adjusting oxygen and carbon dioxide to levels lower than a typical controlled atmosphere storage room so that respiration can be slowed as much as possible before the conditions begin to cause stress on the fruit. It’s also known as monitored ultralow oxygen storage.

“It’s precision agriculture for storage,” Watkins said. “DCA is based on the principle that we are able to measure the response of the fruit to stress — and respond.”

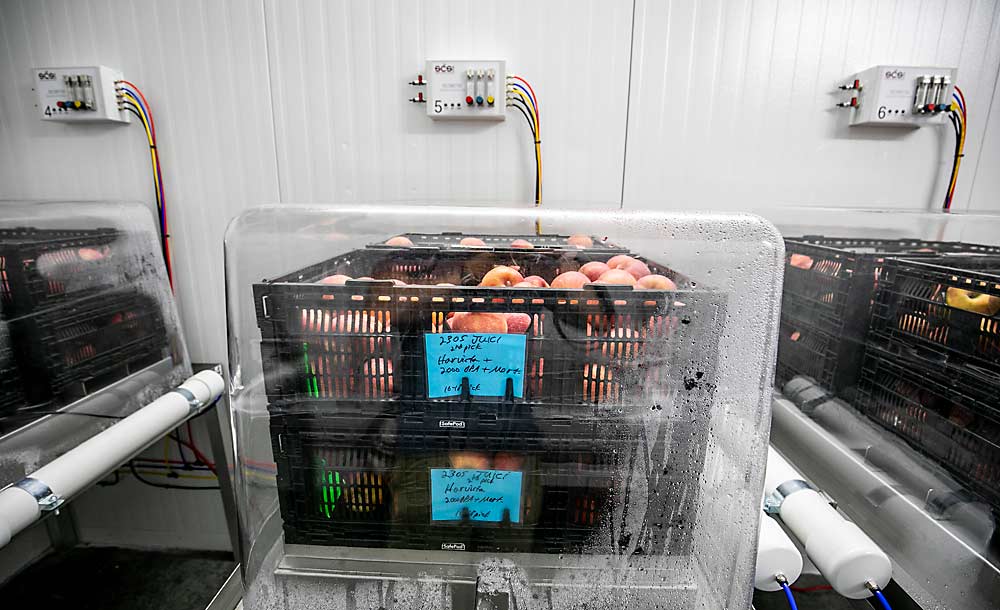

Several commercial tools enable this monitoring of fruit stress, either by tracking the fruit’s respiration rate or a change in the fluorescence of the chlorophyll in the fruit’s skin. The two most common in the U.S. industry are SafePods, sold by Storage Control Systems, which uses the respiration approach, and Harvest Watch, which uses the chlorophyll fluorescence approach.

The research project will evaluate both, Watkins said.

At Washington State University’s Tree Fruit Research and Extension Center in Wenatchee, postharvest physiologist Carolina Torres has both Gala and Honeycrisp in DCA storage with both monitoring systems, as well as regular controlled atmosphere and refrigerated controls. She’s also working with fruit from several different orchards.

“We want to see how (DCA performance) changes region to region and how it changes season to season,” she said.

In addition, she will study WA 38 (marketed as Cosmic Crisp) while the Cornell team will look at NY1 (marketed as SnapDragon). Both are among the wave of Honeycrisp offspring increasingly grown across the U.S. and increasingly challenging warehouse managers.

“I often joke that Honeycrisp never read a textbook about what it is supposed to do as an apple,” Watkins said. “It’s changed our perspective on how varieties are supposed to behave.”

Meanwhile, internal browning issues have been cropping up for Galas in long-term storage. “DCA seems to be a very powerful tool to help reduce that problem,” he said.

In addition to Watkins and Torres, the research team includes Cornell food sensory scientist Robin Dando and economist Bradley Rickard, WSU economist Karina Gallardo, Michigan State University postharvest physiologist Randy Beaudry, and USDA Agricultural Research Service physiologist David Rudell.

—by Kate Prengaman

Leave A Comment