The combination of the ethylene-inhibiting gas 1-MCP (1-methylcyclopropene) with controlled atmosphere has vastly improved the long-term storage of apples and other tree fruits in the past couple of decades.

But the typical method of applying 1-MCP on fruit — fogging or spraying in a sealed room — requires a level of infrastructure beyond the reach of many small growers. Now, there’s another option for the fruit industry: dry sachets placed in a container, where they gradually release 1-MCP.

AgroFresh Solutions, the company that launched SmartFresh two decades ago, offers a few different 1-MCP application methods, including a small, portable dry sachet called SmartFresh InBox. First used in the flower industry under the brand name EthylBloc, the sachet has been around since 2006. In the past 10 years, product usage has expanded into the global fruit and vegetable sectors, said Sarah Enescu, AgroFresh commercial business director for North America.

In July, the California Department of Pesticide Regulation approved the use of InBox on apples, pears, stone fruit, kiwis and avocados in that state. The product was already approved for use on those crops in the rest of the United States.

Customers who use InBox sachets typically don’t have their own storage rooms, or don’t store fruit long-term. The sachets come in three sizes for different-sized containers, Enescu said.

SmartFresh InBox doesn’t require freezing or refrigeration, which makes it more stable and ready to use. Simply open the foil package that contains the sachets and place them in the fruit container, said Daniel MacLean, AgroFresh global external innovation research and development director.

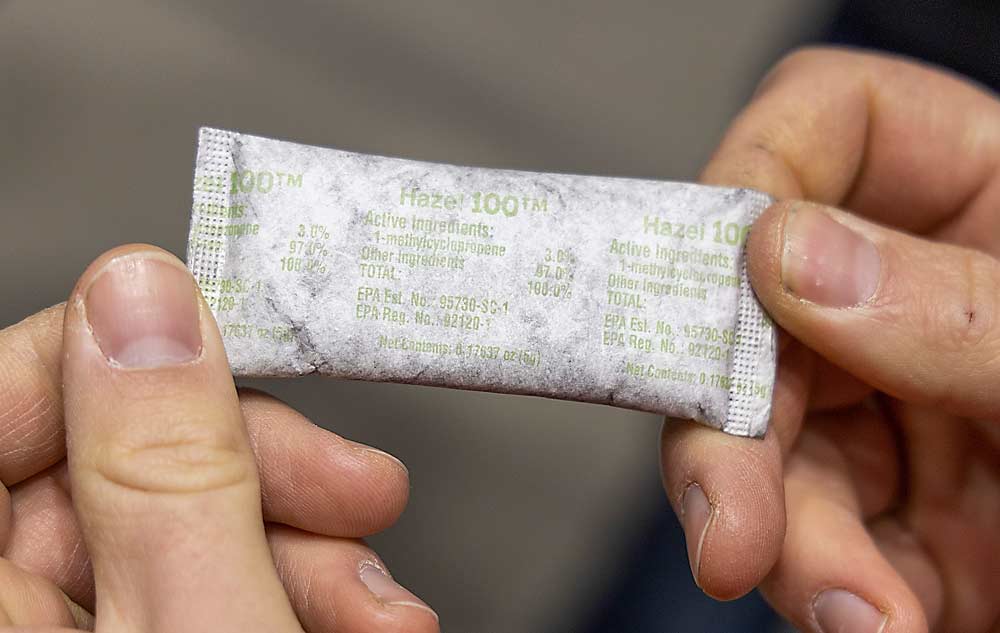

When the original 1-MCP patents held by AgroFresh expired a few years ago, it created the opportunity for other storage technology companies to join the 1-MCP market. One of those companies, Hazel Technologies, created its own dry sachet that is catching on in the fruit industry.

The sachet — a tiny white packet that fits in the palm of a hand — can be tossed into a container of fruit, where it gradually releases a consistent dose of 1-MCP.

The sachets can regulate the storage environment for weeks or, in certain cases, months after cold storage, without leaving residue on the fruit — and without the need for additional technology or operator education, said Hazel Technologies senior marketing strategy manager Kevin McCarthy.

Hazel Technologies, based in Chicago, was founded in 2015. The company receives funding in the form of research grants from the U.S. Department of Agriculture to help solve the problem of food waste in agricultural supply chains, McCarthy said.

Good Fruit Grower reached out to a few prominent postharvest scientists about the Hazel sachets, but most either didn’t respond or declined to comment due to a lack of experience with the product. University of California, Davis professor Barbara Blanco-Ulate has tested Hazel sachets in peaches. Her trials showed that the sachets led to stronger skin and firmer flesh in seven of eight varieties tested, she said.

Growers gave the Hazel sachets positive reviews.

“Compared to traditional 1-MCP deployment, it was a no-brainer,” said Wisconsin apple grower Scott Kee. “I put a sachet in 80 percent of our fruit now. This way I never have to rework coolers and shuffle bins around. I can see the difference in how well the fruit holds in the cooler and after packing.”

Wayne Hollabaugh, wholesale sales manager at Hollabaugh Bros. in Pennsylvania, first used Hazel sachets with the 2021 apple crop. They made an immediate difference. Varieties that are usually soft and mushy by Thanksgiving were selling the following March at full pressure, he said.

“For operations my size, it’s a godsend,” he said. “There’s so much flexibility.”

The Hollabaughs grow nearly 50 varieties of apples, many of them sold direct or by the bin. After harvest, they’re constantly moving varieties in and out of storage rooms. They don’t have the kind of operation that can quickly fill a sealed room to apply 1-MCP via fog or spray. With the sachets, however, they can simply toss one in each bin right off the truck, Hollabaugh said.

The sachets worked well on pears, too. This year, they plan to try them on peaches, blueberries and “darn near everything we don’t plan to sell right away,” Hollabaugh said.

The sachets have to be kept frozen before use, and once the sealed pouch that holds them is opened, they have to be used within a couple of weeks, he said.

Pennsylvania’s Rice Fruit Co. has also used Hazel sachets. The Adams County packing and storage facility is a “heavy user” of traditional 1-MCP, but all the tasks involved — making timely applications in sealed rooms, keeping grower blocks together, closing and opening doors, reserving access for production, counting bins — is a “big hassle,” said quality assurance manager Leighton Rice.

“Sachets make all those issues go away,” he said. “Just throw them in the bin and you’re done.”

Rice said the sachets help greatly with early varieties such as Gala, when it’s best to start 1-MCP treatments right off the truck. Otherwise, the fruit is at risk of ripening too quickly in the first few days.

“The sooner the better for Gala,” he said. “And it doesn’t get any sooner than the sachets.”

Rice’s forklift drivers love the sachets, because they don’t have to be as picky about where they stack bins when space is at a premium. They can stack them in unsealed areas, which opens up more space. Truck drivers don’t like the sachets, however, because applying them adds a step to the receiving process. And each sachet must be removed before the bin goes in the dump tank, otherwise it might end up in a field somewhere, Rice said.

The sachets are a little more expensive than sealed-room 1-MCP treatments on a per-bin basis. Rice said their effects on long-term apple shelf life are equal, maybe even better. This coming season, he plans to treat about half of their apples with 1-MCP in sealed rooms and the other half with sachets. Varieties such as Red Delicious, Golden Delicious and Fuji — which can fill a room quickly and are a little more forgiving in the postharvest environment — will mostly be treated in rooms. They’ll use sachets on Gala and Honeycrisp, especially Premier Honeycrisp, where they’ll use a smaller sachet in each packed box to help them capture a strong early market, he said.

Greg Orchards, a packer in Benton Harbor, Michigan, will use Hazel sachets on apples and peaches this year. The packer has applied 1-MCP via fogging in the past but plans to replace that method with sachets. They decided to try the product after hearing positive reviews from other growers, said general manager Matt Schilling.

In the Pacific Northwest, Mount Adams Fruit has trialed Hazel sachets on pears. The Bingen, Washington, grower and packer applies 1-MCP to apples via fogging in a sealed room but doesn’t use that method on pears because they want pears to ripen after storage, said director of product Ed Ing.

Mount Adams uses the sachets on only a small percentage of its pears. They pack pears in boxes before storage, and they put sachets in boxes destined for long-term storage or long overseas trips. So far, the method has extended pear shelf life and maintained their color, though effects vary slightly based on variety and maturity. Once taken out of storage and kept at room temperature, the pears ripen, he said.

At 25 to 30 cents per box, the sachets are more expensive than sealed-room fogging, but their ease of application can’t be denied, Ing said. •

—by Matt Milkovich

Leave A Comment