Knowledge is power. If you know the fungicide resistance status of pathogens that cause common diseases in your orchards and vineyards, you can dial in disease control by avoiding those fungicides that don’t work well. By avoiding problematic fungicides, you save time, money and, in some cases, the crop.

But sometimes well-intended approaches can have unintended consequences. To help with this, the Fungicide Resistance Action Committee (FRAC) has grouped fungicides by their active ingredients that share potential for resistance. In one scenario, you might learn that you have fungicide resistance to your most commonly used FRAC group, so you naturally choose to not use that FRAC group for the next couple of seasons. To keep your planning as easy as possible, you may simply swap out that problematic FRAC group with one that doesn’t have known resistance. Problem solved! Except, maybe not: Simply changing to a new FRAC group starts selection pressure on that new group, and in a few years, you will be right back where you started. Only now, you may have resistance issues to two FRAC groups, making future management decisions even more difficult.

Fortunately, there are a couple of practices available that focus on fungicide stewardship and can help you design effective pest management programs that not only focus on disease control but also on avoiding fungicide resistance.

Practice 1 — Keep the pathogen(s) guessing!

The top-prescribed approach for fungicide stewardship is alternating FRAC groups in a spray program. In an ideal world, your fungicide inventory would be sufficiently large enough to allow you to complete an entire spray season without duplicating active ingredients or FRAC groups that are moderate to high resistance risks. This approach reduces repeated selection pressure on target pathogens and, thus, reduces the risk of building a resistant population in your orchard or vineyard.

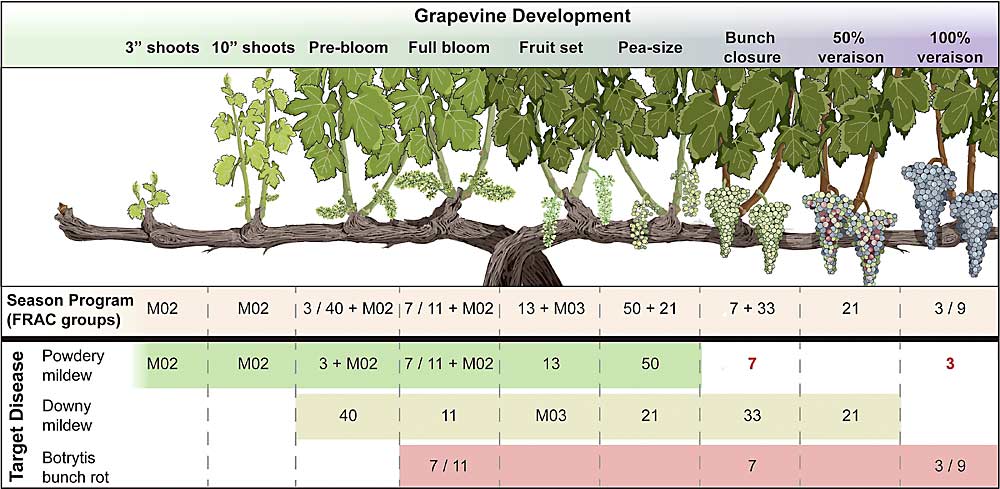

This is easier to do if you live in a climate with low disease pressure and a limited spray season. It is decidedly more challenging when you: live in a high disease-pressure climate; are targeting multiple diseases; and/or these diseases have different management timelines and require specific FRAC codes to maintain control. The key to rotating fungicides in high disease-pressure situations is thinking about both the rotation of fungicides within a program AND the rotation of fungicides as experienced by the target organisms.

To manage rotations effectively, it’s important to plan your fungicide spray program ahead of time. Typically, preplanning of a program focuses on the target diseases, optimizing fungicide timing and spray intervals, and understanding which FRAC groups each fungicide belongs to. However, preplanning also provides an opportunity to consider which fungicides in your program are at low risk, and which are at high risk, for resistance development.

Tips for the fungicide rotation preplanning process:

1) A good fungicide inventory has multiple low-resistance-risk products available for use. Low-risk products can be used alone during periods of lower disease pressure, in tank mixes, or in sequence rotation with higher-resistance-risk fungicides. These products can also serve as last-minute substitutions or additions, if needed, without negatively impacting the intent of your rotation of higher-risk products. What might limit widespread adoption of these types of products is they can be phytotoxic if overused, used on sensitive varieties or used during inappropriate weather conditions (such as high heat or periods of prolonged leaf wetness).

2) A good fungicide program can still include medium- and high-resistance-risk products. These products still have value if you don’t have known resistance in your vineyard or if you use them judiciously. They often have properties like longer efficacy windows, the ability to be absorbed by the plant or minimal negative interactions with nonpesticidal tank mix partners (i.e., foliar nutrients).

A great fungicide program only uses higher-risk FRAC groups once a season, but a good program can still be achieved with repeated use of a FRAC group. The difference between a great and a less-than-ideal or good program is the number of moderate- or high-risk FRAC group applications that are made. If multiple uses of moderate- and high-resistance-risk products/FRAC groups are needed, we recommend that they are both: tank mixed with a low-risk product as frequently as possible and that there are at least two applications of different FRAC groups that target the same pathogen separating the higher risk applications (see illustration above).

Practice 2 — Tank mixing: The one-two punch.

Just like fungicide rotations, tank mixing fungicides (combining multiple ingredients and/or different FRAC groups in a single spray pass) needs to be considered in context of resistance risk of the fungicides used in the tank mix and the target organism(s) of those different fungicides. Some tank mixes function well for targeting multiple diseases in a single application, and some are great for fungicide stewardship and resistance management. Unfortunately, just because a spray is a mixture of fungicides doesn’t mean it is guaranteed to perform one or both functions.

Tips for selecting a good fungicide tank mix:

1) Prepackaged fungicide mixes can be helpful — provided you know what’s in the package! Many companies have premixed fungicides on the market to help with managing multiple diseases, fungicide resistance or both. But it is important to know what the purpose of that premix is — are both ingredients targeting the same pathogen (i.e., designed for resistance management) or are the ingredients targeting different pathogens (i.e., not always designed for resistance management)?

2) Low-resistance-risk fungicides can make great tank mix partners. Low-resistance-risk fungicides go a long way to alleviate selection pressure. They often provide broad control for multiple diseases, may enhance the effectiveness of the partner fungicide and can be inexpensive alternatives to tank mixing two higher-risk fungicides.

3) Keep up those good rotations — even if you are tank mixing! It is important to remember that at least two FRAC groups are represented in premixes, so don’t let that mess up your rotation game! It is also important to switch up tank mix combinations, as repeated applications of the same tank mix combination can lead to the selection of dual resistance in the target pathogen, especially if the active ingredients are considered high-resistance-risk FRAC groups.

4) Consider what the nonfungicides might be in that tank mix. Everyone loves fewer passes with a tractor — that’s why tank mixing is so popular and often includes an application that targets multiple diseases, insects and even foliar nutrient applications. But when there are too many products in an individual tank, problems can arise — such as product precipitation and/or clumping, unexpected phytotoxicity or chemical impacts on efficacy. There can be too much of a good thing, and that is applicable to the number of products being mixed in a single spray application. Always check the labels for product compatibility warnings, try out a jar test and remember: The label is the law!

Conclusion

Good disease management and fungicide stewardship are not mutually exclusive. In fact, when disease is under control, so is resistance selection pressure. While the adoption of cultural practices to reduce disease pressure will always be fundamental to disease management and fungicide stewardship, additional practices such as purposeful fungicide rotations and tank mixing will ensure our available management options for effective disease control last as long as possible.

This work is associated with the project funded by U.S. Department of Agriculture — National Institute for Food and Agriculture — Specialty Crop Research Initiative Award No. 2018-03375 titled “FRAME: Fungicide Resistance Assessment, Mitigation and Extension Network for Wine, Table, and Raisin Grapes.”

—by Michelle Moyer and Charlotte Oliver, Washington State University; Phil Brannen, University of Georgia; Timothy Miles, Michigan State University; Sarah Lowder, Oregon State University; and Melanie Lewis Ivey, The Ohio State University

Want to learn more?

Watch these video resources for more information on how fungicide resistance can develop:

—Fungicide Resistance: What is it and how does it occur? (FRAME) youtube.com/watch?v=AvluVPj_cB4.

—Fungicide Resistance Management (FRAC and CropLife) youtube.com/watch?v=Fw8VXz2SUGs.

Interested in learning more about fungicide resistance management and product stewardship? Visit the FRAME networks website at: framenetworks.wsu.edu.

Leave A Comment