—by Kate Prengaman

Making optimum storage decisions for a warehouse full of apples or pears involves taking lots of samples to assess fruit maturity.

But a new AI-enabled approach developed by scientists at the U.S. Department of Agriculture and Washington State University reduces sampling time and increases the accuracy and consistency of the results.

“Our technicians take two to four minutes per (starch) sample. If we can just take a picture of the tray and use the software to rate it, it’s 10 seconds,” said Austin Wilson, postharvest research and development specialist at Allan Bros. Fruit of Naches, Washington. “The quality of the data is the other big piece. We humans are prone to error, especially with a repetitive task like that.”

Wilson is an early user and collaborator on Granny, a software program that uses image analysis to rate starch levels.

The name stems from the origin of the tool: collecting data on superficial scald incidence in Granny Smith as part of a larger research project that seeks to uncover genetic markers for key mechanisms controlling pome fruit maturity.

“We’re not great at measuring real maturity — starch is the best we have — but it’s really about predicting fruit storability,” said Loren Honaas, research molecular biologist with the U.S. Department of Agriculture. “We need lots of physiological data to find the best traits we can to predict storability.”

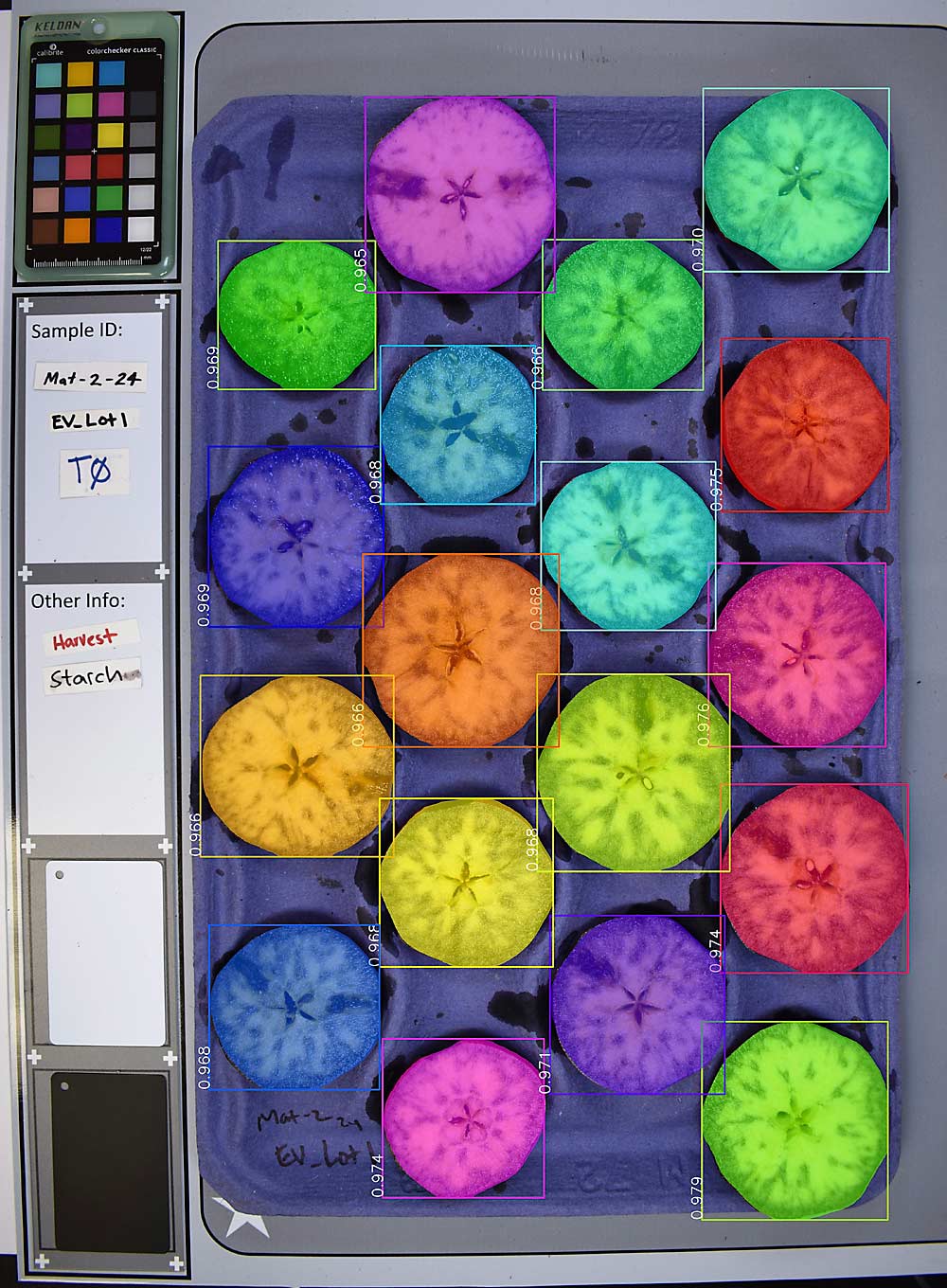

When humans do starch ratings, they use a scale with sample images, typically ranging from 1–5 depending on how much of the fruit flesh is stained dark by the iodine.

Because the analysis is done visually, it was a natural place to leverage computer vision and machine learning tools, said Nhan Nguyen, a former WSU student now working toward a doctorate at University of California, Davis. He designed the programming underlying Granny as an undergraduate student working with Honaas’ collaborator, Stephen Ficklin, a computational scientist at WSU. The program identifies each apple on the tray and then segregates the surface area of each into the percent clearing and percent stained (or the percentage of green peel versus brown, in the case of scald damage), Nguyen said.

“So, it outputs as a percentage of cross-sectional area,” he said. Then, the program translates that percentage to a starch scale rating; from human ratings it learned to match the images to categories on six common industry scales.

“The percentage gives us more meaningful information, but the industry has widely developed protocols to use the scales,” Nguyen said.

Having that higher-resolution data — more detailed than the standard starch categories — should help researchers learn more about what is going on physiologically as fruit matures, and what that means for storability.

“Within a Category 4, there is a lot going on that goes into one big bucket,” Honaas said. “This gives us higher-resolution physiological information, but (the research question is) where is the value for that precision?”

That’s a subject of the ongoing research, but they also learned that the tool could have industry applications now. Wilson listened to a presentation about the scald rating system in 2022 and asked if it could do starch samples as well.

Thus began a collaboration to create a giant dataset of human ratings of starch samples, along with the corresponding pictures, to teach the artificial intelligence how to identify the patterns. Each person doing the ratings might see things a little differently, but if enough samples are included, the result is comprehensive. “You get that wisdom of the crowd effect,” Honaas said.

That’s the biggest advantage for Allan Bros., Wilson said.

“We need that starch data — and with Granny, it’s consistent, it’s going to deliver the same results every time,” Wilson said. “The better we can make decisions on harvest timing or the storage regime the fruit is going into or other maturity-dependent treatments, the better the return for the grower.”

Currently, the Granny program is publicly available in the common programming language of Python, but it takes a tech-savvy person to set it up on a desktop computer. Once it’s set up, it’s easy to run a folder of images with a simple command, Wilson said.

To make it more user-friendly, the researchers recently received a two-year grant from the USDA’s AI Innovation fund to bring in additional collaborators to turn Nguyen’s code into an app-style interface with buttons and drop-down lists that will make it easy for quality control staff to use, Honaas said.

Long term, Honaas said he hopes a company sees potential in the free software they developed and can help get it in the hands of growers. After all, he’s trying to uncover genetic markers for fruit storability, not build apps.

While Granny itself can help make maturity testing more efficient at warehouses, the data it collects also feeds into the efforts to better understand storability. Honaas’ team picks apples at varying harvest intervals and examines their gene activity at that point in time, along with these higher-resolution starch tests and other traditional maturity metrics, to look for patterns that were previously invisible.

“There are massive opportunities to use these kinds of tools,” Honaas said. •

Leave A Comment