Steel materials for trellis construction await use at a new tree fruit block in Royal City, Washington, in August. (TJ Mullinax/Good Fruit Grower)

Growers are considering wood trellises instead of steel. Contractors are reluctant to lock in bids. Irrigation valves are hard to find. Machinery parts take months instead of weeks to deliver.

When discussing current tariff disputes, the tree fruit industry typically focuses on the millions of dollars of fruit that aren’t being sold in foreign ports. But U.S. tariffs on imported goods, namely steel, have had their own ripple effect.

For much of 2018, trellis supply vendors took day-to-day approaches on trellis bids, never certain where steel prices would be, said Ned Rhode, an orchard and vineyard wholesale representative for Bleyhl Farm Service of Grandview, Washington. “We couldn’t tell the customer how long that bid was good for,” he said. “We had to go back to the drawing board every single time.”

Bleyhl custom orders most of its customers’ trellis components.

The United States is the world’s largest steel importer, maintaining a steel trade deficit for more than a decade, according to the U.S. Department of Commerce. The top three sources have been Canada, Brazil and South Korea. In March last year, President Donald Trump imposed a 25 percent tariff on imported steel and a 10 percent tariff on imported aluminum, calling the trade imbalances a security threat.

Since then, the tariffs have dampened imports and made them more expensive. U.S. steel imports through September 2018 were 23.7 million metric tons, down 12 percent from the same period the year before, according to the U.S. Census Bureau, but the value of those imports went up by about 3 percent to $22.7 billion.

U.S. mills rallied to catch up. Since April, the first full month after the tariffs took effect, domestic steel mill shipments are up nearly 5 percent and raw steel production is up almost 7 percent, according to the American Iron and Steel Institute.

Thus, the market has stabilized and, with it, Rhode’s bids, he said. However, prices remain higher and his bids still have shorter price guarantees than in 2017. Many of his clients already had trees ready and had to absorb the higher costs, while others have opted to postpone projects or inquire about wood trellises, which typically have a shorter lifespan.

Tough to budget

Mark De Kleine, who owns a trellis engineering company in Prosser, Washington, has noticed a similar shift in his customer requests. Clients who normally would have asked him about steel trellises now price out wood or hybrid systems, as well. He also has steered some of his clients toward used steel.

He noticed the increases began in February with the publication of a U.S. Department of Commerce Section 232 report linking steel tariffs and national security.

“The minute that report came out, prices just started increasing,” he said.

Rapidly changing prices make budgeting difficult, said Mike Omeg, a cherry grower from The Dalles, Oregon. Some suppliers quoted him 48-hour pricing, others simply listed “market price” on bids for pumps and wells and other projects.

Mike Omeg

Omeg, a proponent of aggressive capital investments in the orchard industry, is known for building trellises with steel, but the past year’s uncertainty has, in part, prompted him to plan some new blocks with wood trellises.

“We need to be able to predict and budget very accurately because the dollars are so big for the investment and the margins in cherries are getting tight enough that you don’t have a lot of wiggle room for sloppiness in your budget,” said Omeg, who holds a bachelor’s degree in economics.

Scarcity of products

The difficulty goes beyond trellises and prices, Omeg said.

Omeg has been trying to purchase steel pressure-sustaining valves for his irrigation system. They cost about $4,000 to $5,000 each. With the tariffs, the Chinese knock-off prices have gone up enough for him to buy domestic.

“But we can’t find the darn things anymore,” he said.

That scarcity is a bigger problem than the price hikes for J.J. Dagorret, president and founder of Automated Ag Systems, a Moses Lake, Washington, farm equipment manufacturer. He has been more put out by the lengthy lead times on orders. What used to take eight weeks now takes three to six months. Sometimes he has to redesign to make way for different vendors.

“That’s time consuming,” he said.

He doesn’t necessarily like higher prices but has tolerated them without plans to pass them on to his customers, said Dagorret, known in the fruit industry mostly for his worker platforms and other harvest assist tools.

For example, when the cost of a Chinese-built cylinder went up by 25 percent, he chose to spend 30 percent more with an American vendor, instead. Each of Dagorret’s machines needs six cylinders at a cost of $50 each, or $300 per machine — a relatively small portion in the cost of a platform, with most generally priced between $60,000 and $80,000.

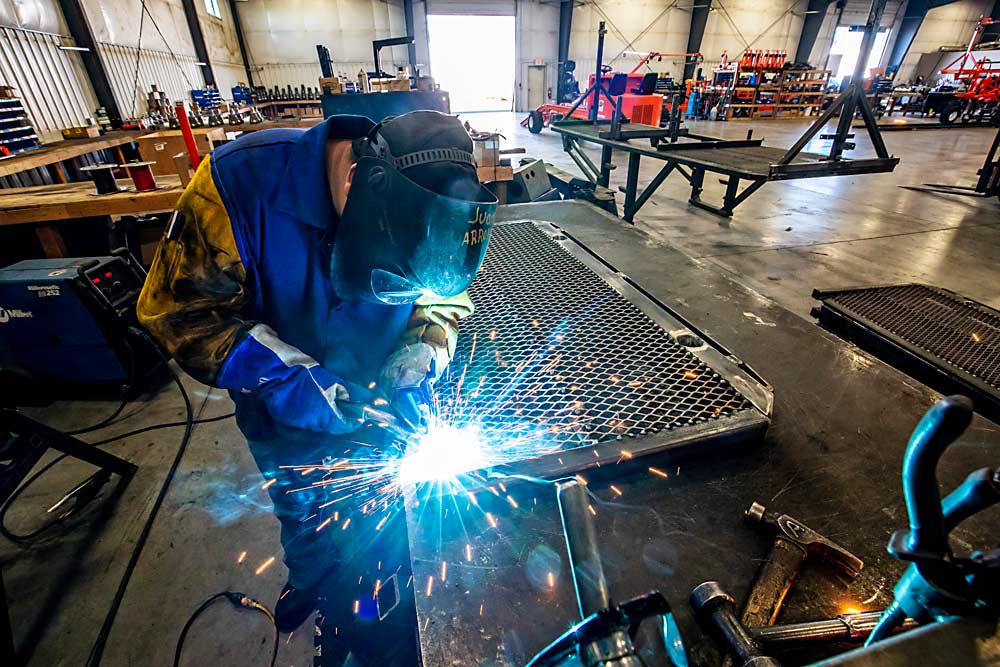

Juan Arroyo welds a steel grate onto a standing platform at the Automated Ag Systems factory in Moses Lake, Washington, last June. Automated Ag’s president and founder J.J. Dagorret says he’s had to make some changes with orders and vendors because of the volatility in the steel market. (TJ Mullinax/Good Fruit Grower)

“It hasn’t been too crazy,” he said. “We’ve been able to get it and gobble it up and not pass it on.”

He hopes more American companies fill the gap.

“There’s opportunity all over the industry,” he said. •

—by Ross Courtney

Leave A Comment