A “dream team” of cherry researchers from across the nation is working on a project designed to help assure the profitability of the fresh sweet cherry industry in the future.

A “dream team” of cherry researchers from across the nation is working on a project designed to help assure the profitability of the fresh sweet cherry industry in the future.

The project, entitled “A Total Systems Approach to Developing a Sustainable Stem-free Sweet Cherry Production, Processing and Marketing System,” was awarded a four-year, $3.9 million grant through the USDA’s Specialty Crop Research Initiative. The rationale behind the project is that, to remain profitable and sustainable, the sweet cherry industry must improve harvest labor efficiency without reducing consumer appeal of the fruit.

Dr. Matt Whiting, associate scientist and Extension specialist with Washington State University in Prosser, heads the team of experts from WSU (Pullman and Prosser), Oregon State University, University of California Cooperative Extension, and Michigan State University.

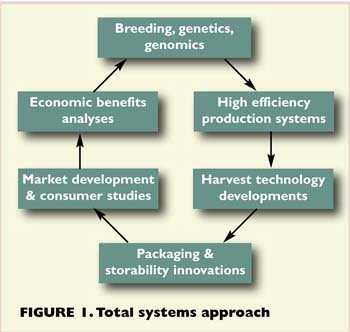

The project’s long-term goal is to improve the sustainability of the U.S. sweet cherry industry by developing a highly efficient production, processing, and marketing system for fresh sweet cherries. The biggest threat to the sweet cherry industry is its dependence on hand labor for harvest, which accounts for approximately 60 percent of annual production costs. The research team will look at innovation, discovery, and outreach that integrates the total value chain, from genetics and breeding to processing and marketing (Figure 1 “Total systems approach”).

The team has six specific objectives:

The team has six specific objectives:

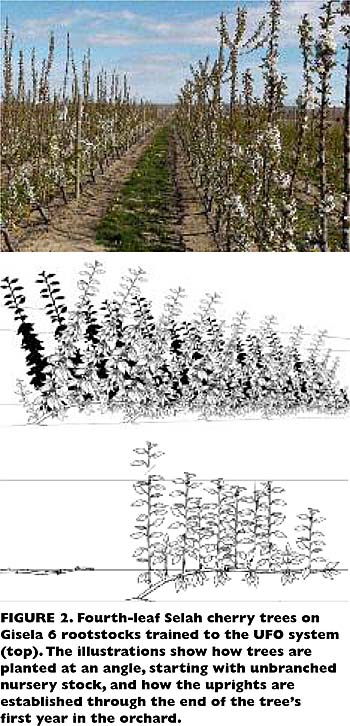

1 Develop highly efficient and productive angled fruiting-wall orchard systems. Currently, most trees in sweet cherry orchards in the United States are not grown in a way that allows for fully mechanical harvesting. To achieve gains in labor efficiency and an increase in the grower’s bottom line, new plantings must be designed to accommodate mechanical harvesting. An alternative orchard architecture dubbed the “UFO” is being studied and developed, and test orchards are being planted in the Pacific Northwest (Figure 2 “UFO system”). Mechanically assisted harvesting technologies for existing tree forms will also be developed and tested in collaboration with Picker Technologies.

2 Establish the genetic bases for sweet cherry abscission. Cherries that separate easily from their stems will be necessary for mechanical harvest. Researchers will study abscission and also work on developing new cultivars that separate easily from their stems with minimal fruit damage and high consumer appeal. A high importance will be placed on making sure that the high quality of fresh market sweet cherries will be maintained.

3 Improve labor efficiency and safety with mechanical and/or mechanically assisted harvest technologies. Sweet cherry harvest is one of the most labor-intensive of all agricultural endeavors, largely because of unwieldy tree architectures, and the lack of mechanical harvesters. Preliminary testing with a mechanical harvester prototype developed by the USDA has shown the potential to dramatically reduce harvest costs compared to traditional hand harvesting (Figure 3 “Prototype mechanical harvester”), and mechanically-assisted harvest systems show promise. Research in this area will focus on three different types of technology: a fully mechanical harvester, a shake-and-catch mechanical assisted harvester, and a mechanically assisted harvest system capable of handling fruit with or without stems.

4 Extend shelf-life and consumer appeal of cherries. The fully mechanized harvester and shake-and-catch mechanically assisted technologies yield stem-free fruit, and this raises concerns over product storability. Researchers will study the shelf life of stem-free sweet cherries, and how to prolong the fruit quality with novel packaging.

5 Develop premium markets for stem-free cherries. Assessing market potential and consumer acceptance for stem-free sweet cherries is critical to this program’s efforts. Without assurances of market potential and consumer/retailer acceptance for stem-free cherries, producers will not adopt the labor-saving harvest technologies the project will evaluate and develop. Results of preliminary consumer preference studies are promising. In a study in Portland, Oregon, for example, a majority of consumers preferred stem-free cherries to standard cherries. Further, consumers appear to be willing to pay the same for stem-free sweet cherries as for those with stems. The team will work with retailers to conduct test marketing studies.

6 Economic models for outreach and adoption. New technologies are often assumed to be too expensive, unproven, or affordable only for large-scale growers. This project will include economic analyses of innovative technological solutions to evaluate the potential for new technology to generate a profit for all growers.

6 Economic models for outreach and adoption. New technologies are often assumed to be too expensive, unproven, or affordable only for large-scale growers. This project will include economic analyses of innovative technological solutions to evaluate the potential for new technology to generate a profit for all growers.

We are in the process of developing a dynamic Web site with lots of great features and information to keep the public informed about our progress and findings. For more information, or to voice questions or concerns, call Tracie Arnold at (509) 430-1313 or e-mail tracie. arnold@wsu.edu.

Leave A Comment