—story and photo by Ross Courtney

Karina Gallardo and Suzette Galinato crunch numbers for growers, but industry outsiders use them as much, if not more.

That’s not bad, said fans of the Washington State University agricultural economists. Researchers, investors and bankers need realistic information about how much it costs growers to produce fruit compared to the revenues they should reasonably expect.

“Those numbers are important to them,” said Mark Hanrahan, a Zillah, Washington, fruit grower.

Policymakers, in particular, need a reference point to see the effects of regulations and laws, he said.

However, Galinato and Gallardo would like more growers to use their enterprise budgets, which are spreadsheets comparing costs versus revenue for fictional, but representative, orchards. Many growers, especially the large, vertically integrated companies, know their own costs down to the penny, they said. Those growers help the two economists write the budgets, which rely on assumptions, or industry standard figures.

To spread the word about the spreadsheets as a tool for the rest of the industry, Gallardo and Galinato worked with a WSU communications team to produce a video that explains how to use them.

“(We) need to increase awareness for these studies,” Gallardo said.

The 14-minute tutorial, funded by a U.S. Department of Agriculture Specialty Crop Research Initiative grant, walks users through the budgets. It’s located on the WSU School of Economic Sciences crop enterprise budget page at: ses.wsu.edu/enterprise_budgets.

Here’s how they work:

First, find the budget for your crop. For example, for one of her most recent additions — an organic Honeycrisp budget — visit the website. Scroll down to find an alphabetized list of crops, from alfalfa to wine. Search for “Honeycrisp” in the field in the upper-right corner.

To just read the budget, use the PDF choice.

But the beauty of the budgets is in their versatility, Gallardo said. If the assumptions don’t match your reality, you can change them. To do that, click the Excel link to download a worksheet with multiple pages. Wherever you see figures in orange, swap in your own packing costs, acreage, tax payments, labor wages or other details.

The best place to customize is in Appendix 5, the raw data table, the video explains. Changes there will ripple through the entire workbook.

For example, Gallardo assumes a manual labor rate of $21.76 per hour. Based on that and dozens of other assumptions, a grower breaks even with a return of $583.24 per bin, as shown on a different page.

“If the return is below this level, organic Honeycrisp apples are uneconomical to produce,” her worksheet says.

However, go back to Appendix 5 and bump up the wage to $25 per hour. The breakeven point jumps by more than $10 to $593.59.

Do the same for orchard manager housing costs, life expectancy of a trellis or nearly anything else. Want a new pickup truck? Plug in the price and find out how it will affect your bottom line.

Outsiders

Like many growers, Hanrahan has a pretty good grasp of his own costs, but he always consults Gallardo’s work to compare.

“For me, it’s a starting point,” he said.

He also calls some of his neighboring growers, for further comparisons.

At times, he disagrees with her assumptions — and she appreciates that, she said.

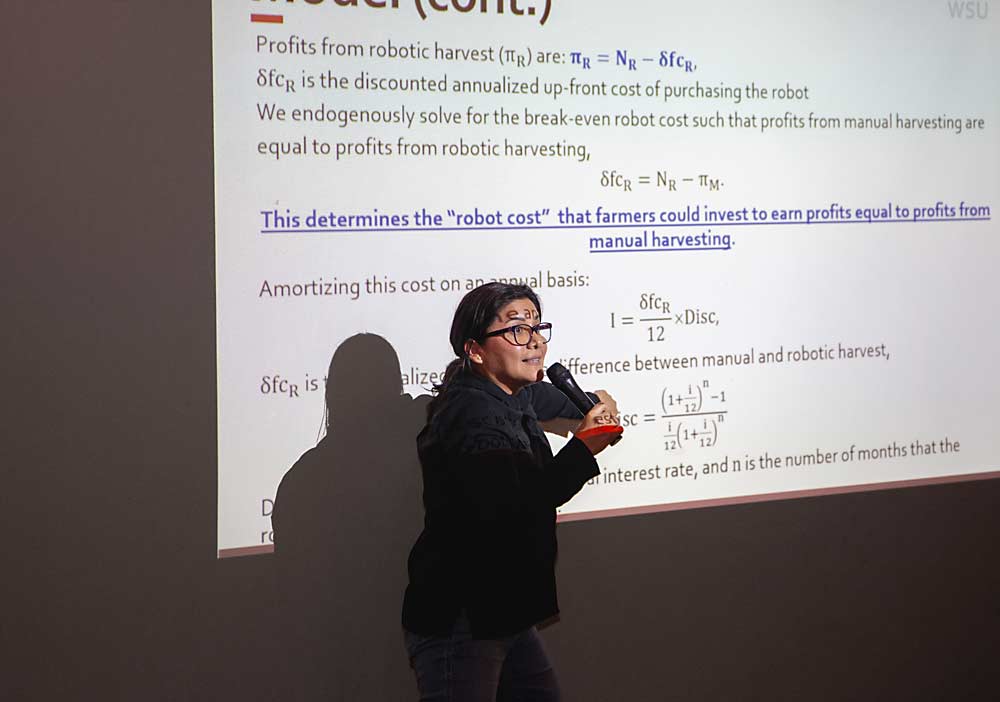

For example, she has been collaborating on a project to estimate the economics of a robotic harvester. There is no such thing on the market now, so assumptions play a big role. One assumption is that the robot would successfully pick nine out of 10 apples, which Hanrahan told her might be too optimistic, especially in the early stages of development.

Hanrahan also argued that the missed apple would not just rot on the tree. A grower would send a crew to clean up behind the robot, adding to the cost of production but also to anticipated revenues with higher yields to the packer.

“That is the type of feedback that we need,” Gallardo said.

She and Galinato have also written economic costs for how much the apple maggot quarantine has saved, the cost-benefit of biocontrols and a break-even point for sliced pears.

Later this year she will release the first enterprise budget for WA 38, the WSU apple marketed as Cosmic Crisp. Updated budgets on conventional Gala, Honeycrisp and Granny Smith also are on the way, she said.

Clark Seavert, an Oregon State University economist, suspects most growers don’t understand their own costs as well as they think they do. Enterprise budgets help “cut through the coffee shop chatter,” he said.

He also relies on them to build scenarios in AgBiz Logic, an online farming cost and revenue analysis platform at: agbizlogic.com. The tool has a library of enterprise budgets from across Western states that he updates when economists publish new ones.

Those drive all sorts of budgeting scenarios, such as the payoff of orchard netting, the costs of purchasing automated technologies, expected revenue disruptions from climate change and the costs of reducing greenhouse gas emissions.

“It all starts with enterprise budgets,” he said. •

Leave A Comment