—by Kate Prengaman

Researchers are four years into an ambitious, nationwide research project aimed at ushering in an era of precision nutrient management for vineyards.

“The key breakthrough — if we can get there — is remote sensing tools that can detect nutrient status in the grapevine canopy,” said project leader Markus Keller, professor of viticulture at Washington State University. “That would lead to mapping of nutrient status across the block, which would lead to variable-rate nutrient management so you wouldn’t apply nutrients where you don’t need them.”

Such precision application should save growers money in inputs, protect the environment from excess nutrient runoff and leaching, and improve fruit quality.

To catch up on the HiRes Vineyard Nutrition project, which includes researchers at seven institutions in five states growing wine, juice, table and raisin grapes, Good Fruit Grower talked with Keller and Patty Skinkis of Oregon State University, the extension and outreach lead. The project is funded by $4.75 million from the U.S. Department of Agriculture’s Specialty Crop Research Initiative and will wrap up next fall.

Skinkis said the project has three primary pillars: development of NPK-specific sensors; viticultural research to better understand nutrient thresholds and the best timing and techniques for sampling; and precision agriculture integration, to figure out how to turn the data from sensors into maps for management.

“We’ve made strides in all three areas,” she said. There is still a lot to wrap up over the next year to turn the research into tools — sensors, nutrient sampling recommendations, economic models and precision management approaches — that growers can use.

Sensors

For commercially available sensors, the industry might have to wait even longer. For the research project, three teams of engineers in Washington, New York and California have been using very expensive hyperspectral cameras, which scan the canopy in hundreds of wavelengths across the light spectrum, along with a host of other sensors. They then sift through that data to find the wavelengths that show the strongest correlation with the nutrient sampling data. They then need to prove it’s consistent, year over year and cultivar over cultivar.

Once winnowed down, the best nutrient-specific wavelengths could be built into more affordable multispectral cameras that growers or service providers could mount on tractors or drones, Keller said, similar to those already on the market for NDVI or infrared sensing.

The sensors in development don’t measure exactly the amount of nitrogen in the leaves, like a tissue sample would, but instead can map relative variation across the block.

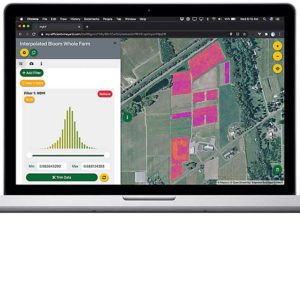

“Uploading the data from a sensor to a platform, like myEV, can make a map of low, medium and high zones,” Keller said. “Just bracketing nutrient status (that way) would be a major step forward, because we have no spatial sampling today.”

Some of the sensors do gather data on the vine-by-vine scale, Skinkis said, but among the next steps is deciding, with their committee of industry advisors, the practical level of precision.

“From a sensing standpoint, we can do it, but it’s a lot of data processing,” she said. “We’re not going to manage to the vine scale, but we can do better than we did before.”

Sound nutrition strategies

Researchers needed to set up trials with known nutrient deficiencies and excesses, to establish a proving ground for sensor development, Keller said, and that presented an opportunity to update and refine tissue sampling and nutrient management guidelines.

Today, Skinkis said, many grape growers use tissue sampling sporadically, to diagnose a problem if they see leaf symptoms or just to check in every couple of years. They also usually collect leaves across an entire block or vineyard and combine them into a single sample, losing any spatial resolution.

Improved recommendations on timing and tissues to sample, tailored for each grape crop, would help growers get stronger information from their current sampling method, Skinkis said. Researchers gathered data on leaf blades and petioles at bloom and veraison, the traditional choices, and added additional options, including dormant pruning wood, young shoots (during shoot thinning stage) and fruit, which might be able to provide additional insights with tissues growers are already removing.

For potassium, phosphorus or magnesium, the trial data suggests that sampling every few years might suffice, unless growers are managing a known deficiency, Keller said.

“We have vineyards that we’ve been applying no nutrients to for four years, and we see no impact on the fruit. It takes years for deficiencies to show up,” he said. “We’re discovering that vines are quite resilient.”

But for nitrogen, there is significant spatial variability and value to managing it, especially in Eastern Washington, according to trials there that show growers should apply nitrogen annually to replace the nutrients lost in the crop and the fallen leaves each year.

Spatial strategy

Think of the project like puzzle pieces. Yes, the pieces are still under construction, but in New York’s juice grape vineyards, researchers are also working on how to put the whole project together.

Using myEV, a free platform born from a prior precision vineyard management project led by Terry Bates at Cornell University (available online at: efficientvineyard.com), the New York team built variable-rate nutrient application maps using the data from the sensors in development. Variable-rate spreaders can read those maps and apply nutrients based on simple zones of nitrogen demand.

Even using yield maps, which are already available to growers who harvest mechanically, could guide a precision nutrient replacement program, based on the research team’s findings about how nitrogen, potassium and phosphorus deplete each year.

“If you know what you are removing with every ton you are harvesting, it can become a simple replacement program,” Keller said. “If you harvest 5 tons per acre in one section and 10 tons here, that’s twice the juice and twice the nutrient replacement.”

In irrigated West Coast vineyards, where most of the nitrogen is applied as fertigation, that precision model may be more difficult to adopt, Keller said.

“You lose that spatial resolution unless you break your irrigation system down into zones,” he said, or switch back to bulk nutrient applications to take advantage of the emerging precision approaches. Developing variable strategies through a drip irrigation system is part of a new research project Keller and colleagues at OSU are working on, he added. •

Leave A Comment