Modern manufacturing plants use computer vision to track every step of the production process. The approach revolutionized manufacturing, said Matt King, a former Boeing engineer who wants to bring the same approach to orchards.

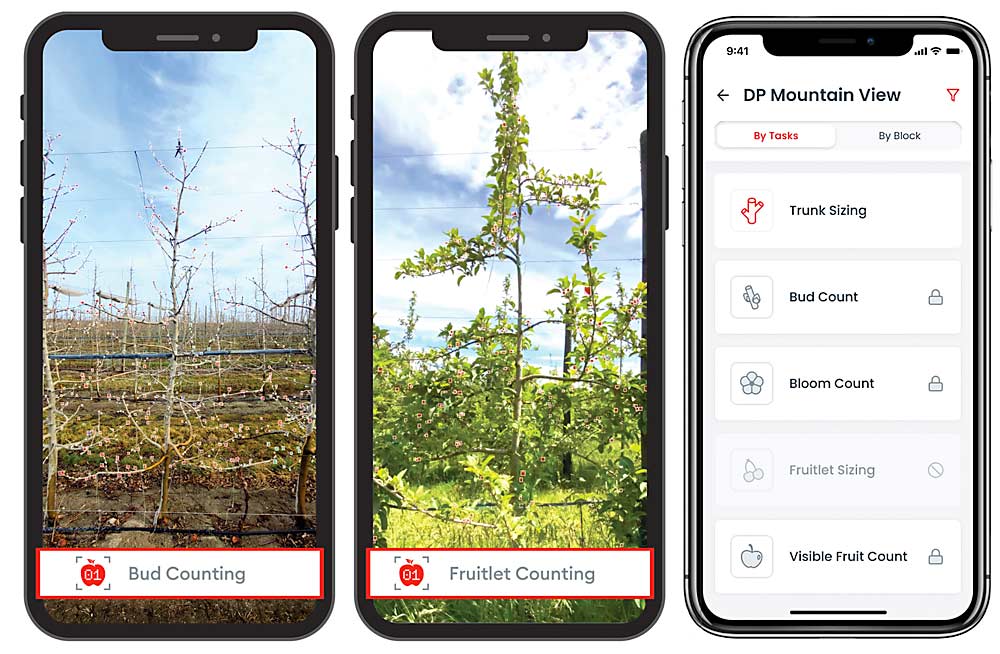

King, now CEO and co-founder of FruitScout, envisions his company’s precision crop load management app as that critical instrumentation able to track buds that turn to blooms and on through fruitlets to full-color fruit at harvest, with an eye on the economically optimum crop load goal.

“I think of this as process instrumentation. We’re instrumenting the process growers use to manage their crops,” he said.

It’s an approach he used in his first ag tech company, which used camera systems to track plant growth and health in a greenhouse. That led to connections with the tree fruit industry, which led to FruitScout, King said. The company launched last year with a handful of pilot customers and plans a wider rollout later this year and next.

The instrument itself is a smartphone. The FruitScout app guides users as they walk down an orchard row, taking a picture of each tree. How many trees should be sampled to get a representative sample depends on variety, King said. Highly variable Honeycrisp may need 15 percent of the block sampled, while Gala just needs 5 percent, he said, but the company is fine-tuning these recommendations.

From the images collected, the technology counts buds, then blooms and finally fruitlets to help growers optimize crop load management strategies. Growers set targets in the app, and FruitScout’s dashboard tells them how close they are through each step of the season. It also suggests a target fruit count based on the size of the trunk.

“Our objective here is to make it possible for every grower to do precision crop load management,” King said. But the data only has value if growers use it. “Technology is easy; changing how people do their jobs is difficult.”

One of King’s first customers, Washington Fruit and Produce Co., was already a big proponent of precision crop load management.

“There’s a tremendous amount of counting that goes on,” said Darrin Belton, vice president of orchard operations for Washington Fruit, one of the state’s largest vertically integrated fruit companies. He described a process in which managers set target fruit counts for each block, based either on historical production or trunk cross-sectional area for young trees, then they count dormant buds, figure out how many need to be pruned off to hit the target, test out pruning strategies to see if they’ll arrive at the ideal outcome, count buds again, and then send pruners out to work. The counting process repeats at bloom and fruitlet stages, to guide additional management.

“Even with our excruciating process, there’s some variability. How do we take that variability out? By sampling more trees,” Belton said. That’s the appeal of technology like FruitScout, to reduce the burden and potential human error in all that counting.

FruitScout, in particular, appealed to Washington Fruit because of the smartphone-based system, he said, and because King and other company representatives have been good to work with.

“The power of this tool is there’s no barrier to entry,” he said. “I don’t need a drone or a special ATV, and we’re already paying people to walk through our orchards.”

Last year, the company did pilot testing with the technology, Belton said, sampling a modest number of trees at a lot of ranches, allowing every area manager to try out the tool. “There’s no doubt it’s a participation sport,” he said. They are still counting to validate the app’s results and are investing company time in helping FruitScout refine its approach.

The system can only count the buds, blooms or fruitlets the camera can see, and the percentage it can see depends on the tree architecture, Belton said. It can probably see more buds in a fruiting wall than a central-leader system, for example, but FruitScout’s algorithms are starting to account for that, thanks to machine learning from data collected in many different systems, combined with hand measurements for validation.

This year, Washington Fruit plans to target the technology to more modern blocks, where the cameras can see most of what they need to see, and for cultivars more prone to biennial bearing, such as Honeycrisp.

“One of the best things you can do for fruit quality is crop every year consistently,” Belton said. Just by getting the crop load right, “I can carve out money on a per-acre basis to make this pay.”

Last year, FruitScout charged customers $1 per tree. That made sense to make the case to growers looking to test the technology, King said, but now he’s shifting to a per-acre service fee going forward.

“What we realized is that the customer wants to manage more trees, we want them to do more trees, so let’s charge a flat rate,” King said.

This year, FruitScout will also offer a fruitlet sizing tool to inform thinning decisions. Instead of repeatedly using calipers to measure the fruitlet growth to understand which fruit are developing and which will drop, the camera and algorithms can do it, King said. Moreover, he said that by measuring a large enough sample — 500 fruitlets — you don’t have to return to measure the exact same ones every time.

—by Kate Prengaman

Leave A Comment