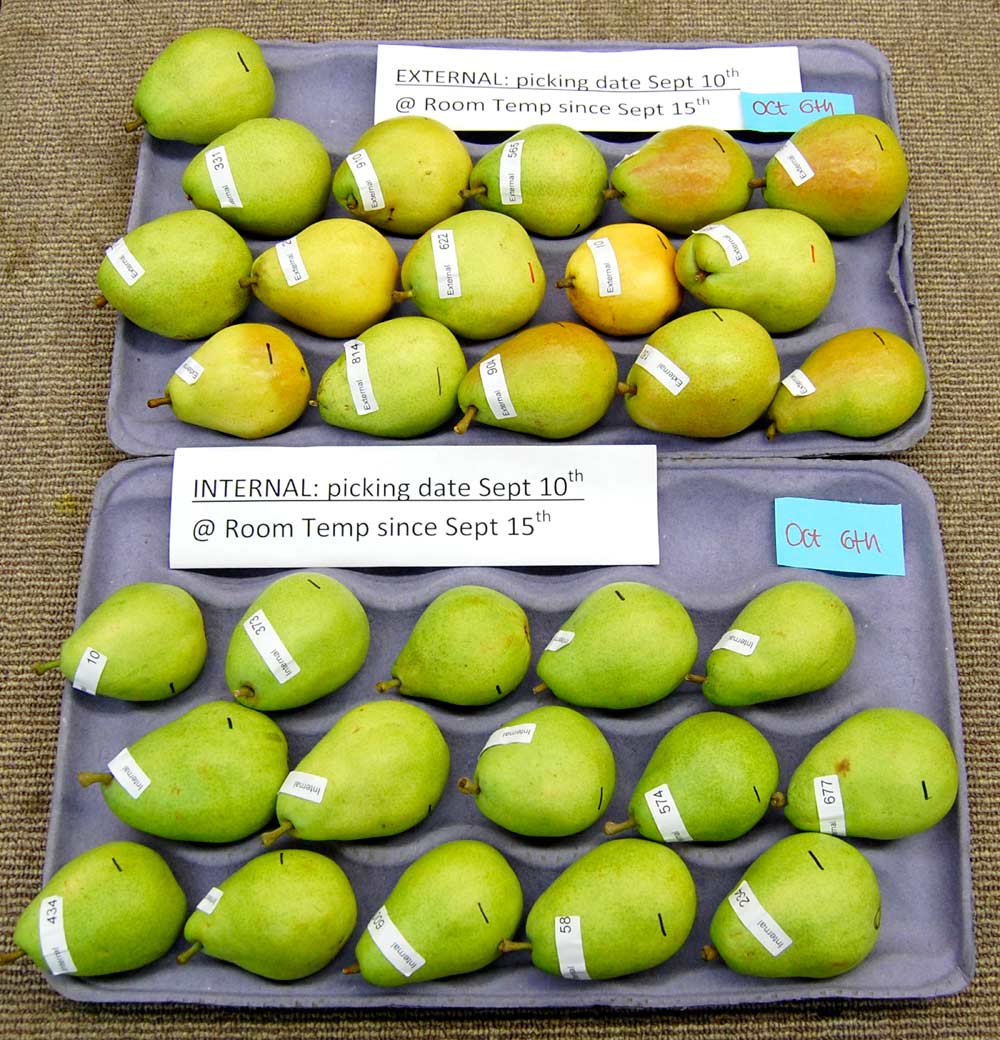

These “external” (top tray) and “internal” (bottom tray) d’Anjou pears were kept at room temperature for three weeks following harvest in September 2014. The “external” pears, which grew in the outer regions of the canopy, were blushed with more yellowing and were more ripe compared to the “internal” pears, which grew in the inner part of the canopy and were greener and slower to ripe. (Courtesy Sara Serra)

The lack of true dwarfing rootstocks means many Pacific Northwest pear orchards remain planted in low-density spacings, frequently with open-vase trees and voluminous canopies. Most new orchards aren’t planted at high density as in Europe and other fruit tree areas in the world.

Spray regimes in these orchards are far less effective than if the canopies were narrower and thinner, and mechanization of harvest and sorting of fruit isn’t as feasible. Light, too, hits the trees in different ways depending on the position in the canopy, causing varying fruit quality within the same tree.

Pear fruit variability within a large canopy has been the subject of several Washington State University and U.S. Department of Agriculture Agricultural Research Service projects in an effort to help growers try to streamline pear production and quality for the market.

“The point is, the fruit quality is all built in the field — pruning, thinning, training system are all factors impacting the fruit. We have to think about the whole picture,” said Sara Serra, assistant professor at WSU’s Tree Fruit Research and Extension Center. Serra told growers at the WSU Fruit School in March that researchers working in the project observed pears from large-canopy trees all being picked into the same bin.

“We wondered if those pears have the same maturity, the same storability, the same quality.”

These “external” d’Anjou pears, harvested in September 2014 from an open-vase style orchard in Cashmere, Washington, grew in the outer regions of the canopy where they received plenty of sunshine — at least 70 percent light interception. (Courtesy Sara Serra)

Researchers focused on green d’Anjou pears for the study, given that 98 percent of U.S. d’Anjou production is in the Pacific Northwest. They opened by picking pears according to their position in the canopy — internal and shaded versus external and more exposed to the sun — and storing them at room temperature for 24 days. They immediately noticed differences in color and chlorophyll degradation, with internal fruit being very green and changing very slowly compared with external pears.

That immediately led them to wonder about the biochemical changes within the fruit based on canopy position. Thanks to the metabolomic analysis carried out by USDA’s David Rudell within this project, they found that many of the chemicals they could detect that were related to light (photosystem metabolites) were at higher levels in the internal fruit; chlorophyll levels were high in those pears, and they were less ripe.

Conversely, “ripe” volatile metabolites, which contribute to aroma, were found higher in the external fruit (peel and cortex). “That means Anjou ripening is really influenced by the position where the fruit is located in the tree,” Serra said.

In yet another study, researchers built light maps measuring how much light — and what kinds of light — are intercepted in the different positions inside the tree. At least 70 percent of light interception was the threshold to discriminate external fruit in contrast to internal, which had less than 30 percent of light hitting the fruit. Fruit in the lower canopy also developed to smaller sizes than external fruit, and the production was limited in the internal shaded areas of the tree.

“There are really differences in the spectra of the light based on position in the tree,” she said. “In the shade, we are losing power of the direct light (mainly diffuse light). This impacts the development of the fruit. It’s a considerable difference and a huge variation in the development of the fruit.”

These “internal” d’Anjou pears grew in the inner part of the canopy where it was much shadier, receiving only 30 percent or less light interception. (Courtesy Sara Serra)

Taking it one more step

So how does storage play a role? A final study in Cashmere, Washington, used fruit from an open-vase, multileader, low-density planting d’Anjou orchard from the 1970s. Fruit located externally in the tree and receiving at least 70 percent of the light interception was kept separate from internal fruit hit with 30 percent or less of available light. Researchers then divided the fruit into four postharvest groups for evaluation: harvest, three months in CA (controlled atmosphere), six months in CA and eight months in CA, as well as each of those storage durations followed by a seven-day ripening period. Each time they pulled fruit out of controlled atmosphere storage, they performed a fruit quality analysis and a metabolomics evaluation of biochemical changes.

Overall, they found that external fruit at harvest were bigger with more yellow background color and higher soluble solids. Internal fruit were less ripe and greener with no blush. The differences were consistent across all fruit they pulled from storage; after eight months and seven days of ripening, internal fruit were still less ripe than the external fruit.

In terms of firmness, there was no significant difference between the internal and external fruit until eight months, when the internal fruit was firmer. With a seven-day ripening period, internal fruit was firmer at both three and eight months.

The difference is consistent and significant, Serra said. All the external fruit showed higher dry matter compared to internal fruit, whether it was measured immediately after removal from cold storage or after a seven-day ripening period.

The dry matter is built up in the field and influenced by light availability, which isn’t an issue in the Pacific Northwest growing regions.

However, if growers can optimize the light interception, moving from a low-density to a little bit higher density planting and narrowing the tree canopy in a little more organized way, they can benefit with higher dry matter levels in the fruit preferred by consumers, she said.

What does it all mean?

This series of studies showed that harvest maturity varies depending upon the fruit’s position in the tree; fruit size and quality differed for external and internal fruit after three, six and eight months of controlled atmosphere storage, and external fruit were riper each time. Peel chemical analysis also indicates that position in the tree has a major impact on storability and quality.

The resulting recommendation: It’s a pain, but growers should avoid picking all the fruit together, Serra said.

“Keep the fruit separate. Start in the field with external fruit in the same bin, because they can be stored with a different regime,” she said.

In addition, Serra and colleagues noted that external fruit began to develop superficial scald after six months of storage, while internal fruit did not.

Finally, “New picking protocols, at harvest sorting strategies and new higher density orchards — using the bi-axis system to control the vigor — should be considered for the future to reduce losses and repacking and to achieve a consistent eating quality for our consumers”, she said. “So they will come back to buy pears again.” •

—by Shannon Dinnny

Leave A Comment