When McDougall and Sons planned their newest packing facility 10 years ago, they knew they were planning for an unknown future.

Rather than wait, however, they planned for flexibility.

“I wanted to have as few walls as we could manage,” said Bryon McDougall, company vice president, so the space could be adapted over time. And adapt they have.

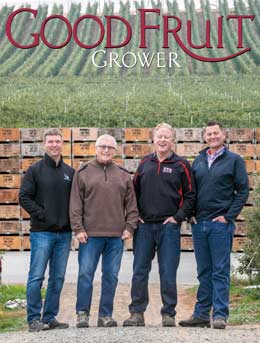

“This line is a bit like Frankenstein,” he said on a recent tour with Good Fruit Grower, highlighting the innovations they’ve added in recent years, including two styles of pouch bagging technology. “We see what works, what doesn’t. Things are always changing.”

In 2014, the line was built to handle 500 bins an hour for tray packing and Euroboxes, said Stuart McDougall, Bryon’s father and the retired company president.

Now, at least half their production goes into bags, and despite their investments in bagging machines, “we lose one-third to one-half of our production capacity to this bagging bottleneck,” Bryon said.

That experience, and what he sees as the industry’s ongoing era of packaging innovation and turmoil, has him prepared to approach designing the next line in reverse. They have space for it alongside the existing line, ready and waiting, since they designed the facility with room to grow.

“The worst thing we could do is invest in a new line right now, because we just don’t know what is coming next,” Bryon said. “All this packaging change means we’ll have to build our next line from the outside in.”

That means first examining packaging approaches and the technology required to execute, and working backward on capacity. It also means thinking about how to efficiently move out all of the packed product. “The line itself is going to be straight, we know that,” he said.

Change can be hard, but the company also embraces it.

“They were the first ones in the industry to automate pouch bagging, and they openly did tours for competitors to show what they learned,” said Bob Mast, president of CMI Orchards, the sales and marketing company in which McDougall and Sons is a partner. “If a retail partner is asking for a difficult but innovative packaging (that may improve sales), we make a phone call and they say, ‘Let’s see if we can make this work together.’”

Bryon credits his packing technology manager with the technical ability to find solutions. Take the pouch bags, for example. For their apple line, they were interested in pursuing a cherry bagging technology they saw at an expo, but they worried that the force of the apples in the fill drop would create punctures. So, his team rigged up a lift to slowly lower the bag as the apples fill it. They ultimately invested in eight modified machines.

Those machines were bagging Galas on the day Good Fruit Grower visited — another change they had to adapt to.

“When we first got into pouch bags, our marketers told us it’s about branding for the premium varieties,” Bryon said. When he asked if they would ever need the capacity to bag Galas, the belief was that retailers would never see the value.

Times obviously changed, and the McDougalls now know better: Never say never.

“‘We’ll never need to do that’ — it’s a kiss of death,” he said. “CMI is an innovative sales and marketing company, so we always have to be ready for change.”

—by Kate Prengaman

Leave A Comment