—story and photos by Ross Courtney

—photo by Kate Prengaman

University researchers in Oregon and Washington are developing a robot that fertilizes an orchard with the ideal amount of nutrients, tree by tree.

Informed by smart sensors, artificial intelligence technology, historical data and vigor indicators, the automated tool sprays the ground beneath each individual tree with a precise amount of nitrogen.

Underneath each squirt of spray lies two complex systems: one that recognizes each tree in the block, so it knows where to spray; and another that determines how much to spray, based on a host of tree-specific vigor data. The research collaborators hope these new technologies nudge the tree fruit industry farther down the road toward tree-level management with other precision chores such as chemical thinning, plant growth regulation and more.

“You could get more bang for your buck,” said Joe Davidson, associate professor of robotics at Oregon State University.

Fertilizer robot

Davidson and his colleagues built a prototype applicator during a four-year project funded with a $210,000 grant from the Washington Tree Fruit Research Commission. OSU has contributed money since that grant concluded in 2023, and the team plans to seek more funding from national sources such as the U.S. Department of Agriculture, said Davidson, head of OSU’s Intelligent Machines and Materials Lab in Corvallis.

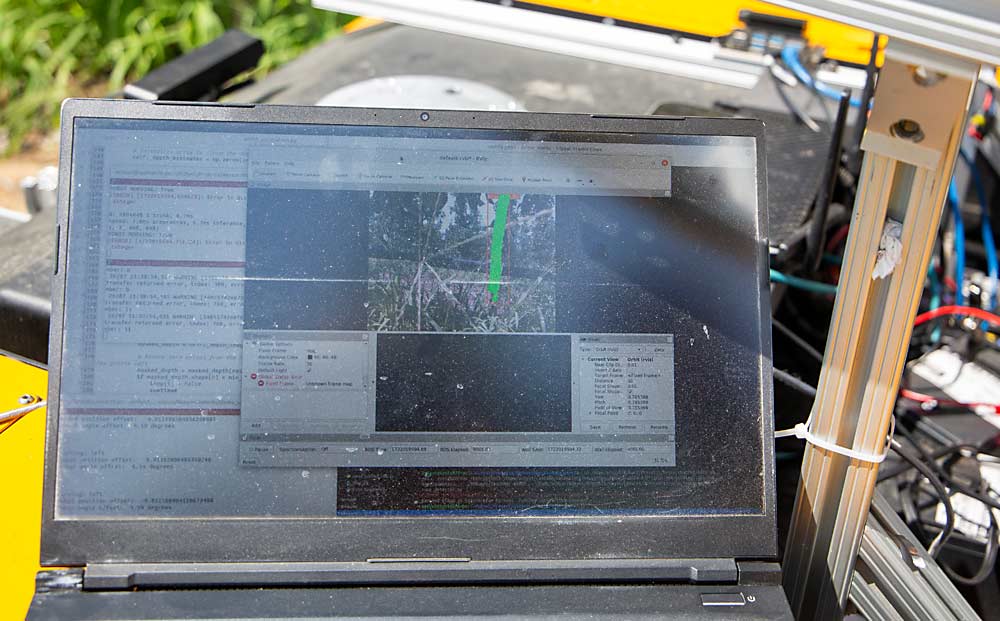

The sophisticated machine relies on a sensor — a traditional camera with a depth-finding function — to scan each tree and trigger the sprayer. Mounted a few feet behind, the sprayer emits liquid nitrogen, usually in the form of a calcium nitrate solution.

Guided by an orchard map drawn in advance, the computer’s camera sees and “learns” the location and identity of each trunk — much like facial recognition — to keep its bearings under the canopy where GPS doesn’t always work.

Davidson’s team first built the applicator onto a Warthog, a small, self-driving vehicle that’s available commercially. This year, they converted the geolocation portion of the machine into a modular kit that could be mounted on a traditional tractor or off-road vehicle, Davidson said. Not many farmers own a Warthog, but they all have a tractor.

That’s how the device knows where to spray.

To determine the nitrogen need, the computer feeds on several horticultural indicators of vigor:

—Trunk diameter, measured by sensors in real time.

—Canopy growth, measured by the machine’s camera at different times during spring.

—Pace of leaf senescence. Trees with leaves that turn yellow earlier in the fall have less nitrogen than trees that maintain leaf color.

“The hope here is when we combine several different parameters together, the decision is more robust,” said Manoj Karkee, one of Davidson’s collaborators and director of the Washington State University Center for Precision and Automated Agricultural Systems in Prosser.

Karkee hopes to eventually add shoot growth, yield and previous years’ quality data to the algorithm.

The nitrogen sprayer is just one of numerous orchard robotics projects on which the laboratories of Davidson and Karkee collaborate.

They also have tools that prune, pollinate and thin. Most of those machines rely on technology — developed by Davidson and fellow OSU professor Cindy Grimm — that creates digital twins of orchard blocks to train the computer programs. Grimm also collaborated on the nitrogen applicator.

Uniform goals

The goal of tree-by-tree nitrogen application is to create an orchard block with uniformity of canopy, even if the soil is not uniform, said Ashley Thompson, Oregon State University extension specialist.

“That’s the heart of precision management,” said Thompson, who spearheaded the horticultural aspects of the project, including leaf sampling.

Soils in the Northwest’s growing regions can vary within blocks, she said. A layer of basalt rock can hide inches deep or tens of feet deep, for example, or river rock can be heavy in one spot but absent just a few feet away.

In the end, precision management should lead to less fertilizer use, among other efficiencies, said Dave Allan of Allan Bros., a Yakima Valley fruit company that hosted project trials in its Jazz apple block near Benton City, Washington.

“I’m quite confident that, with time, we can build a model that will be pretty accurate at dispersing nitrogen to the trees that need it,” he said.

Allan and Karkee first began discussing robotic precision nitrogen application about 10 years ago.

Robotic fertilizer application — robotic anything, really — requires years of computer learning, exposing the algorithm to more and more and more data. This fertilizer robot is good so far but needs more lessons, Davidson said.

“I think we’ve got the parts and pieces, but we don’t have enough data to say our model is going to work perfectly all the time,” he said. •

Leave A Comment