Off-target sprays waste money.

That’s why grower Julie Bosma was eager to test out a smart sprayer kit that assesses the canopy and adjusts the nozzles in real time to avoid overspraying dormant or early season canopies, adapts to canopy variation and pauses entirely if there’s a gap where a dead tree was removed. In apple blocks in the Yakima Valley, where she has used the system, she’s reduced spray materials by 35 percent.

“With the spray savings we are seeing, it can easily pay for itself in a season,” Bosma said. After buying one this spring, she ordered six more this summer. In older Bing blocks, where there is more canopy variation, she thinks savings could be as high as 50 percent, but she hadn’t crunched those numbers yet.

The technology that’s turned her Rears airblast sprayer into a smart sprayer was developed by U.S. Department of Agriculture researchers in Wooster, Ohio, led by Heping Zhu. Properly calibrated sprayers reduce chemical waste and environmental impacts, he said, but growers rarely have time to calibrate for every block and every application.

“Most people use 100 gallons per acre rate, regardless of whether they have small trees or big trees or 100 trees per acre or 1,000 trees per acre,” Zhu said. “We designed computer programs and an electronic control system to control the spray output so we can maintain the constant amount of spray per tree canopy volume, rather than rate per acre.”

Designed as a control system that can be added to any existing airblast sprayer, Zhu and his team hoped to get the precision technology to growers in a cost-effective way.

They licensed it to Smart Guided Systems, an Indiana-based engineering company that’s worked with Kubota, John Deere and turf sprayers on precision and automation. CEO Steve Booher said that when he saw Zhu’s work, “I looked at my management and said, ‘This is where the money is going to be.’”

The commercial kits now available couple solenoid valves that allow each nozzle to adjust the flow rate based on the lidar imaging of the canopy. Lidar, which stands for light detection and ranging, uses laser light pulses, which bounce off things, and a receiver that measures the time it takes for the reflected pulses to bounce back to estimate the distance of the object — add enough points and you get the shape.

“We can retrofit any brand of airblast sprayer on the market,” Booher said. “We spray in ounces per cubic foot, which is the way trees ought to be sprayed, but you couldn’t do it until now.”

A 24-nozzle sprayer kit costs $27,000. It takes a technician for Smart Guided Systems or a local dealer, such as RDO Equipment in the Pacific Northwest, about a day to set up the kit, but if they are doing several at once it is more efficient, he said.

Eventually, Smart Guided Systems hopes to hand its early customers to a growing number of local dealers, Booher said. Also, talks are in the works with several sprayer manufacturers worldwide, with plans to license the technology to be incorporated into new models.

Bosma said it will require a “dedicated and committed spray supervisor” to configure the system and train people how to use it properly.

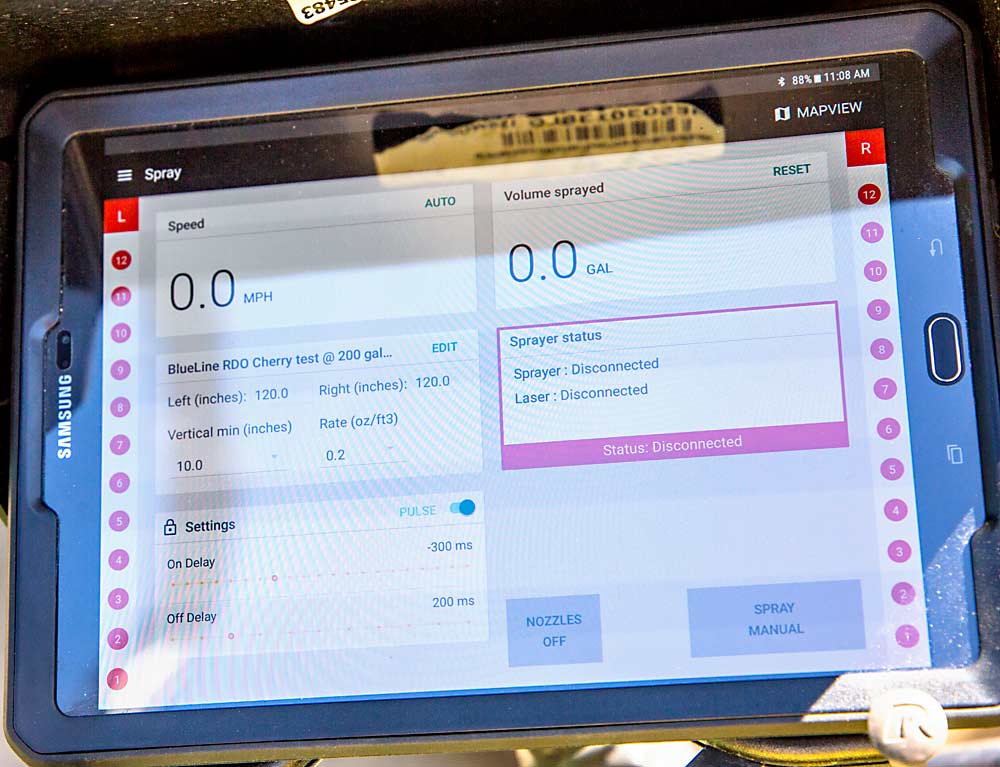

Henry Bosma Orchards general manager Angel Aguilar said the switch to using the tablet isn’t easy for many “old-school applicators,” but he is using his excitement about the technology to motivate people.

“With time and patience, I think I can get most, if not all our guys using it,” he said. “Instead of flipping a switch, you touch the screen. It’s cool watching the machine work as you drive the tractor, only spraying where it needs to.”

Innovation continues

Next, Smart Guided Systems hopes to leverage the data the sprayer collects to serve other precision farming goals growers have, Booher said, such as counting trees, determining the relationship between canopy density and yield, or identifying poorly performing vines or trees.

“We’ve got so much data available, so what do we do with it?” Booher said.

The lidar maps of the canopy are made in real time to adjust the sprayer, but they are not saved because they are too large. But in a new sensor orchard project (See “Sensor Overload” on Page 8) organized by the Washington Tree Fruit Research Commission, researchers want to use the canopy volume and density calculations from the lidar system to see if they add value in terms of smart management.

“It’s the ideal data we want to have to do anything related to canopy management,” said Lav Khot, an agricultural engineer at Washington State University. Assessments of canopy vigor could guide irrigation or variable rate nutrition programs.

Khot is also running a trial with the smart sprayer in WSU apple blocks, to optimize application rates for modern, high-density apple tree architecture. The amount needed per cubic foot of canopy to get good coverage might be even less in fruiting wall systems than in the bulkier canopies for which the smart system was developed, he said.

Bosma, for her part, is talking to a company about developing a way to sync the sprayer data on application time and place with the weather data she gets from another sensor company, to integrate with her spray record program.

“The amount of hours of tedious work on spray records is enough to drive a person insane,” she said. “We thought: If this program could talk to that program, you’ve basically automated my spray records.”

Booher didn’t rule that possibility out, but different record keeping requirements in every state make it complicated.

This year, the company focused on upgrades to make the smart sprayer system, which runs on a tablet, more user friendly. Soon, a “work order system” will enable a manager to program the boundaries for each application so that operators can’t accidentally repeat a row after refilling a tank or spray the wrong block.

Eventually, the risk of human error could be reduced even further, Khot said. The autonomous tractor technology now available from John Deere and others uses lidar, too. These sensors are expensive, but one could conceivably run both the autonomous operations on the tractor and the intelligent sprayer, and provide the insight for smart canopy management strategies, he said. “That’s the value proposition here,” Khot said.

In the meantime, going further with each tank, thanks to more accurate application, will also reduce labor costs, Zhu said. •

—by Kate Prengaman

Leave A Comment