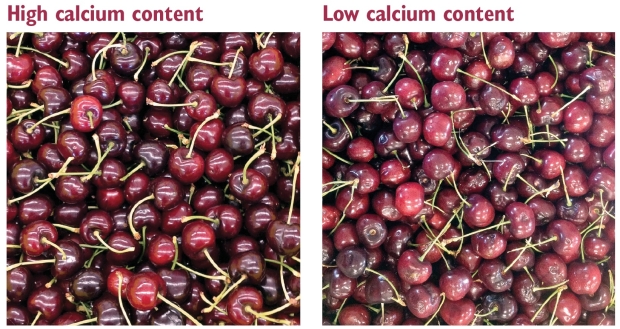

Skeena cherries after three weeks of storage on the left are from an orchard with high tissue calcium content of about 600 ppm. Cherries on the right are from an orchard with low tissue calcium content of 400 ppm after three weeks of cold storage. (Courtesy Yan Wang)

Oregon State University researchers have found that pre- and postharvest application of calcium can improve the ocean shipping quality of sweet cherries.

As export markets become more important because of the expanding Pacific Northwest cherry crop, more cherries will be shipped by ocean, a trip that can take several weeks.

Sweet cherries shipped to distant markets are subject to various arrival problems, including fruit softening, flavor loss, skin darkening, pitting, splitting, decay, and stem and pedicel browning.

Dr. Yan Wang, post-harvest physiologist at OSU’s Mid-Columbia Agricultural Research and Extension Center in Hood River, has found ways to reduce pitting, one of the more important storage issues.

Sweet cherries have high respiration rates and are highly susceptible to mechanical damage, Wang said during a winter cherry meeting in the Northwest.

Pitting, which can be caused by heat and mechanical damage, results from peel depression that occurs after the fruit’s mesocarp cell layers die and dry. Pitting from mechanical damage (dropping) has been shown to occur during harvesting, when hauling from field to packing house, and during packing.

Additionally, cold fruit are more susceptible to pitting, as are some varieties, like Skeena and Sweetheart.

Calcium plays a key role in the fruit’s cell wall structure and strength and respiration. However, fruit are often deficient in calcium due to its low mobility in plants.

Acid soils, high growing temperatures, water stress, high humidity, wide fluctuation in soil moisture, low crop load, and high nitrogen and potassium levels can all contribute to low calcium levels in fruit.

Wang sampled Skeena and Sweetheart cherries from four commercial orchards and found fruit calcium levels ranging from 300 to 600 parts per million dry weight. “In the survey, fruit that had higher calcium concentrations were also the firmest and had the least amount of pitting,” he said.

“Cherries with higher calcium content tend to ship better and have better storage potential than those that have lower calcium levels,” Wang said. The difficulty is finding a way to quickly boost calcium levels in the fruit.

In trials over the last several years, Wang explored improving cherry shipping quality by increasing fruit tissue calcium content through preharvest calcium sprays and adding calcium during postharvest hydro-cooling. Both methods show potential.

For the preharvest calcium sprays, he studied Lapins and Skeena in two orchards and found the best results of enhancing calcium tissue content came from six weekly applications, beginning at pit-hardening and up to one week before harvest.

Nine weekly applications had no advantage over the six, and two applications at pit hardening and one week before harvest was not enough to increase calcium content in fruit tissue.

Rates of about 0.1 percent calcium worked best, Wang reported. Leaf burning was observed when calcium rates were higher than 0.15 percent calcium based on calcium chloride and calcium citrate.

“Frequent applications were found to be more important than exact spray timing,” he said, and added that leaves were more susceptible to burning during the early development stage.

Wang tested several different calcium formulations (calcium chloride, calcium nitrate, calcium citrate, “Cal-8,” and “Chelate Ca”). He found that chelated calcium at 0.05 percent calcium and Cal-8 at 0.2 percent calcium (their label rates) were more effective in improving fruit firmness than calcium chloride (at 0.1 to 0.15 percent calcium), calcium nitrate (at 0.1 to 0.15 percent calcium), and calcium citrate (at 0.07 percent calcium of its label rate).

If sprays were made six times on a weekly basis, both calcium chloride and calcium citrate decreased fruit size—although size was not a problem with any of the other calcium formulations.

By enhancing fruit tissue calcium concentrations through the preharvest sprays, Wang found improved shipping quality in terms of reducing pitting, decay, pedicel browning, skin darkening, and losses of firmness and acidity after three weeks of cold storage.

Wang also investigated adding calcium chloride to hydro-cooled water as a way to increase calcium content. Hydro-cooling fruit shortly after harvest is commonly done to eliminate field heat.

Adding calcium chloride to the hydro-cooling water at 0.2 to 2.0 percent calcium and running fruit through the hydro-cooled water for five minutes under research conditions was enough to significantly increase the tissue calcium content without fruit uptake of chlorine.

Wang’s hydro-cooling addition increased calcium content in Lapins, Sweetheart, Skeena, and Bing by 30 to 190 percent. The increases were dependent on the calcium rate and cultivar.

Benefits of adding calcium chloride to the hydro-cooling included:

—Increased fruit firmness

—Reduced pitting susceptibility

—Reduced splitting potential

—Reduced respiration rate and maintained acid and flavor

—Reduced decays

He also found that low rates of calcium chloride (0.2 to 0.5 percent), helped keep stems green in fruit held in storage for three weeks. However, stem quality was damaged if higher rates of 1 to 2 percent calcium were used.

Wang also conducted the hydro-cooling trial under commercial settings by adding 2,040 parts per million of calcium (Opti-Cal) to the hydro-cooling water at a commercial cherry packing house.

Six lots of Bing and Tieton cherries were treated with calcium in the hydro-cooling water. The calcium increased firmness of most of the fruit, though not of fruit that was very firm to start with (firmer than 350 grams per millimeter). But it did decrease pitting in all the lots.

Wang will continue his calcium research this year, expanding it to more varieties and gathering more data, including effects on return bloom, yield, size, and storage quality. •

Leave A Comment