Over the past ten years I have initiated a number of research trials that, when taken together, tell an important story about the link between apple quality and profitability. I often quote my mantra that “we are in the food business” along with McDonald’s, Wal-Mart, and even the slow food movement.

What I mean by this is that if consumers do not like what they receive, they will not come back for a second helping. I would like to highlight some findings of these studies in the context of the ever-increasing volume of apples coming from Washington State.

Consumer study

The first study looked at how consumers evaluate apple quality. This is important information as they are the final customers. Teaming with Dr. Roger Harker of Plant and Food New Zealand, an internationally known consumer expert, and Ann Colonna of Oregon State University’s Food Innovation Center, we conducted a series of studies to determine what quality aspects consumers consider the most important.

The first study looked at how consumers evaluate apple quality. This is important information as they are the final customers. Teaming with Dr. Roger Harker of Plant and Food New Zealand, an internationally known consumer expert, and Ann Colonna of Oregon State University’s Food Innovation Center, we conducted a series of studies to determine what quality aspects consumers consider the most important.

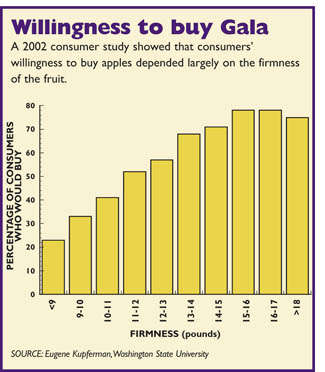

It was clear that firmness and crispness are of greater importance than other quality attributes such as soluble solids, acidity, starch, and juiciness. If the apple is not firm enough, consumers are just not interested.

So, what is an acceptable level of firmness at time of consumption? These studies showed that when consumers ate a 14-pound pressure apple, they would be willing to buy a second one; apples that were softer were less attractive to consumers (see “Willingness to buy Gala”).

Once the firmness requirement was met, consumers reported that they disliked apples with high starch levels. Consumers like apples that are sweet as possible and reported that apples with low soluble solids taste like cardboard.

Packing house study

Concurrent with these studies, I surveyed apple quality across many packing houses in Washington to determine apple quality at time of packing. It was depressing to compare the minimum quality requirement of 14 pounds pressure and the legal minimum quality standards with the actual firmness of the apples. Forcing packers to sort to meet a minimum firmness standard of 14 pounds would have meant that huge numbers of apples would have gone down the cull chute. This was pointed out quite clearly in my discussions with the Washington State Horticultural Association’s Grade and Pack Committee. Although there was interest in raising the minimum standards for firmness, the economic reality of having high cullage dissuaded any proposal to raise standards.

Distribution and handling

Distribution and handling

We also examined the deterioration in apple quality as the apples traveled from Washington to their destinations in cities across the United States. We added apples to commercial trucks going to either Atlanta or Dallas and followed them through the distribution system to the retail stores. We noted that most of the fruit arrived in good condition, with the exception of those apples shipped warm and those that were soft. These weaker apples lost quality during shipping. Packaging material was important to protect the apples from bruising when the apple boxes were tossed from one pallet to another at distribution centers.

At retail, we sampled apples from large refrigerated displays and smaller nonrefrigerated boutique displays. It appeared that turnover of the product on the retail display was more important than whether the display unit was refrigerated. Apples on refrigerated displays averaged only 55°F rather than the target temperature of 34°F.

Retail study

To determine what consumers experience when they buy Washington apples, a number of my colleagues and I undertook a study of the quality of apples in midsized supermarkets across the country. In seven regions, postharvest scientists went shopping for Washington apples during the same weeks each year for three years. We purchased apples from the crop years of 2001, 2002, and 2007. Temperature and prices of fruit on display were recorded and the apples brought to the lab for quality evaluation.

In terms of appearance at retail, punctures were the prevalent problem. It was hard to determine whether the punctures came from the packing/shipping process or as part of the distribution/retail process. Wax whitening was seen in southern markets, which is a turnoff for most shoppers as the fruit look as if there is a chalky pesticide on the fruit. Bruising was a far less of a problem in 2007 than in 2001 for all varieties except for Braeburn.

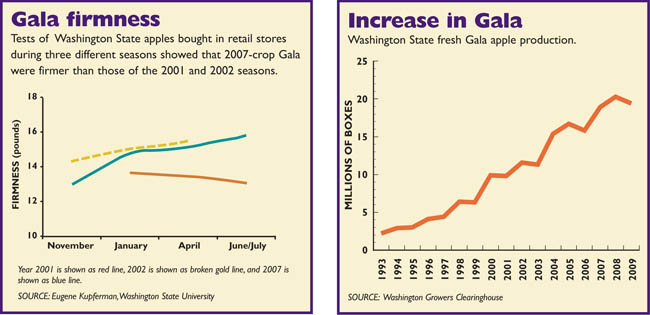

Some of the most interesting data came from the fruit we examined in late June. There were strong differences in the quality attributes of fruit sampled in June 2002 (2001 crop) and those sampled in June 2008 (2007 crop). The apples we sampled at retail in 2008 were much firmer than those sampled in 2002. The strongest gains in firmness were from Gala, Golden Delicious, and Red Delicious, followed by Granny Smith and Fuji. Braeburn was significantly less firm (see “Gala firmness”). Justifiably, this was reflected in the higher prices charged for the firmer apples, even when adjusted for inflation.

Firmer apples

The Gala story is most interesting when one considers that the volume of Washington-grown Gala apples has skyrocketed (see “Increase in Gala”), forcing an extension of the marketing season for what was once thought to be a short-storage apple. We have not had the funds to repeat our packing house sampling, but I am confident that apple firmness has risen. The obvious question that comes to mind is why? We were not able to bring in regulations about firmness so the answer must have come through technology.

There have been three major postharvest discoveries in the last 100 years. The first was the discovery of the naturally occurring plant hormone, ethylene, by Drs. Burg and Burg in Florida in 1967. The second was the discovery of what is now called controlled atmosphere storage by Drs. Kidd and West in England in 1920. The third is the development of 1-methylcyclopropene (now sold as SmartFresh) by Drs. Blankenship and Sisler in North Carolina in 1996. I can only surmise that these postharvest tools, together with better horticulture in the orchard, more attention paid to harvest maturity, and improved fruit segregation have come together to provide consumers with higher quality fruit.

Consumers are our final quality control agents, and the profitability of our industry is in their hands. Whether it is accomplished through regulation or technology, in order for Washington to remain at the top, we cannot forget that the consumer must be satisfied with every apple we send to market.

Leave A Comment